Machine building

L'automatisation BFP est active depuis 2010. De nombreux instruments sur mesure ont été construits au fil des années pour les industries des boissons, de l'emballage, du bois et de l'agriculture, pour les environnements de production, les laboratoires et la R&D ainsi que les centres de recherche. Malheureusement, des clients comme AB InBev, BP, Solvay et d'autres nous empêchent de partager nos créations car nous sommes liés par un accord de confidentialité que nous respectons bien entendu.

Pour la construction de machines, nous faisons appel à nos partenaires réguliers CTRL-Matic et Cloud-Consulting depuis près de 10 ans.

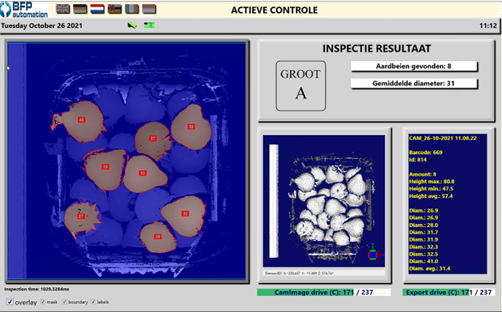

3D Fruit Sorter met Cognex laser camera

Product fiche Fruit Sorter with 3D Vision camera

CLASSIFICATION AND REGISTRATION OF STRAWBERRY PUNNETS

The 3D FruitSorter consists of a 3D laser camera that classifies a filled punnet with strawberries based on the measured diameter. The 3D visualization technique is able to create a high-quality image that is easy to process with the vision tools, from which a sorting can be realized according to the sorting classes:

Large 2A: strawberry diameter > 35mm

Large A: strawberry diameter between 31-35mm

Small: strawberry diameter smaller than 31mm

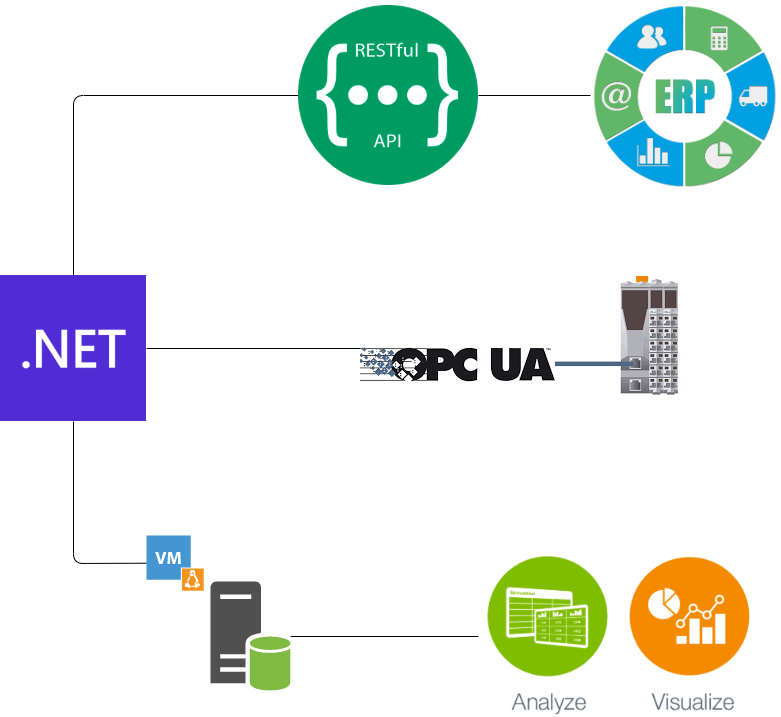

The Vision unit performs the diameter measurement on strawberries located at the top of the punnet. Several combinations of vision algorithms are used for this. The result of the classification is communicated via a Profinet connection to the parent control so that the end result can be registered in an SQL database.